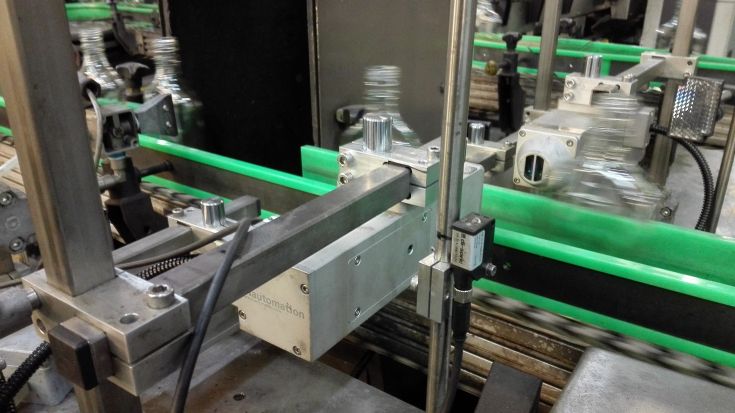

A quality drink needs a quality bottle

Depending on their size and shape, glass containers need a minimum thickness to safely protect the contents during filling, storage and transportation. At the same time, containers should not be thicker than necessary in order to minimize manufacturing and shipping costs.

Since production is subject to certain process fluctuations, containers require a nominal thickness that is higher than the minimum thickness. If all containers are checked for compliance with the minimum thickness, the nominal thickness can be reduced, since containers that are too thin may be rejected.