Reliably clean

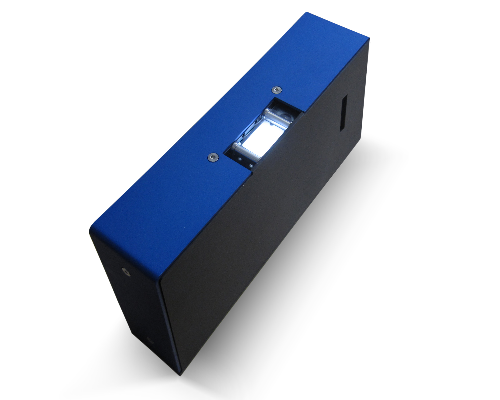

Integrating a Wiper I or Wiper II into your automated dispensing process ensures that dispensing needles as well as jet and spray valves are cleaned, thus giving you reliable and reproducible dispensing results.

Our Wipers are usually placed on a quick-change plate. When the tape needs changing, the connecting cables thus remain in the machine, meaning that in time-critical processes a replacement device can be inserted within seconds.

If the Wiper can remain in the machine for tape replacement, Direct devices can also be used. Here, the connecting cables are connected directly to the device. The overall height is then slightly (12 mm) lower.